Technical Guides

Rubber Expansion Joints - Rubber Vibration Absorbers - Spring Hangers

Rubber Expansion Joints

Characteristics & Usages

Characteristics:

-

Flexibility: Can manage different types of movement (axial, lateral, angular, torsional).

-

Vibration Damping: Reduces vibration from equipment.

-

Sound Insulation: Absorbs and isolates noise.

-

Chemical Resistance: Can be resistant to chemicals, depending on the rubber type.

-

Pressure Resistance: Built to withstand certain pressure levels.

-

Temperature Resistance: Operates within a specific temperature range.

Usages:

-

Piping Systems: Compensates for thermal movement and absorbs vibration.

-

HVAC Systems: Isolates vibration and noise.

-

Water/Wastewater: Absorbs movement and stress from surges.

-

Chemical Processing: Handles corrosive substances and movements.

-

Power Generation: Manages thermal and mechanical movements in cooling systems.

-

Marine Applications: Absorbs movement and vibration on ships and platforms.

-

Food and Beverage Industry: Uses food-grade materials to absorb movement and allow for cleaning.

Rubber Expansion Joints Length

We can manufacture all kinds of length according to different standards. We can also tailor made length based on your special applications

Rubber Expansion Joint Pressure

The data shown in the diagram is for regular usages. We can manufacture rubber expansion joints for higher pressure applications by adopting enforcement rings, control rods and kevlar liners.

Rubber Materials and Applications

-

EPDM: First choice for hot water, steam, oxidising chemicals, animal and vegetable oils. Excellent for sunlight and ozone. Good for high and low temperature applications

-

NEOPRENE: Suitable for water, sewage, oxidising chemicals and non-aromatic hydrocarbons. Good for oil resistance

-

NATURAL: Suitable for water, air, most moderate chemicals, low acids and alkalis. Good resistance for abrasion. Not suitable for exposure of strong sunlight, ozone, oil or petroleum

-

NITRILE: Suitable for most hydrocarbons, oils and petroleum fuels and hydraulic fluids. Not suitable for exposure of strong sunlight, ozone or high temperature

-

HYPALON: Suitable for most acids, alkalis, industrial chemicals and aliphatic hydrocarbons. Very good resistance to ozone, sunlight and abrasion

-

BUTYL: Suitable for animal and vegetable oils, water and many oxidising chemicals. Particularly good for low gas permeability. Not suitable for petroleum fuels or oils.

Flange Standards

Our rubber expansion joints are equipped with flanges that meet all kinds of international standards such as GB, CB, DIN, ANSI, JIS, TABLE, BS4504, UNI and etc.

The flanges can be made of Q235, SS304, SS316, Cast Iron and etc.

Major coating methods are Galvanization and PVC coating.

Union Standards

Our rubber expansion joints are equipped with Unions that meet all kinds of international standards such as BSPP, BSPT, NPT, DIN and etc.

The unions can be made of Tinplate and Cast Iron

Major coating methods are Galvanization and Electrophoretic coating.

Control Rods Installation

When a rubber expansion joint is installed in a piping system that is anchored on both sides of the joint, control rods are not required. If only one side is anchored, the joint must be prevented from extending, either by control rods or some other methods.

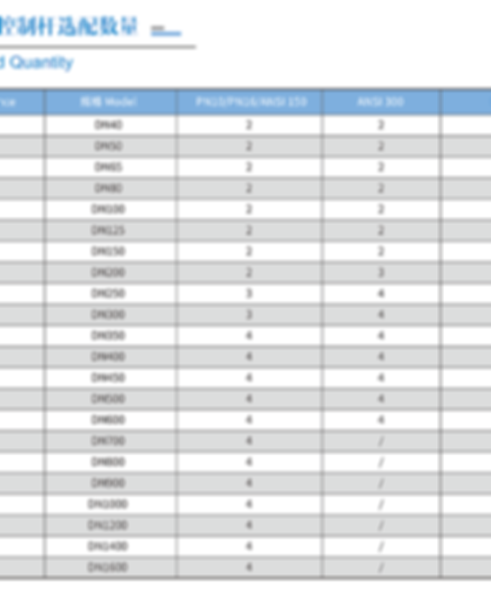

Control Rod Quantity & Size

The right table shows the recommended quantity for different rubber expansion joints models.

The below table shows the dimension of different size control rods

Installation Guidelines

-

Make sure that the sealing faces of the rubber expansion joint bear against mating flanges that are flat and clean over the whole width of the joint

-

Insert flange bolts with the bolt heads facing the rubber body and nuts on the pipeside

-

Do not over tighten

-

Do not paint over the rubber body

-

Do not use flanges with uneven surface

-

Tighten the bolts crosswise, taking up the tension gradually until all the nuts are evenly tightened

-

Check tat the tightness allows no leakages after the joint has been brought up to pressure

Rubber Expansion Joints Maintenance

-

New rubber material will loose up over a period of time. So it is a good practice to re-check the tightness after a few days

-

Under the normal working conditions, the rubber expansion joints will last for many years. However, it is recommended to inspect the installation, the cracking and swelling at least once a year

Rubber Expansion Joints

Storage

-

Spare rubber expansion joints should be stored in a cool and dry place. They should never be exposed to direct sunlight. They should be stored flat with no weight on top of each other